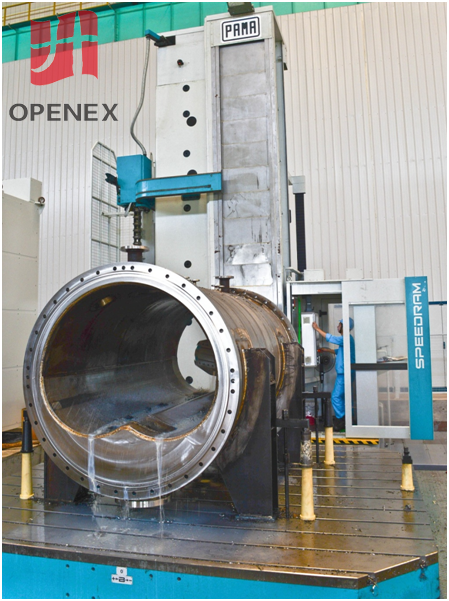

Recently, we have successfully finished a machining task for a mixing silo component. This component is used in the Chemical fiber mixer for a international first-class polyester equipment manufacturer.

Being as core component of a mixer, this mixing silo requires high machining accuracy. We use our Itally PAMA speedram horizontal boring and milling machine to complete this machining task.

This PAMA speedram CNC boring and milling machine caters for high precision, power and structural rigidity machining requirements. Finally, the customer is satisifed with our product and praised highly for our machining quality.

We provide custom metalworking service especially for large and heavy steel components.

Our large machining service includes: large CNC gantry milling, large turning and milling, large vertical CNC turning, large vertical boring mill, large horizontal boring, large horizontal turning and milling.

Some of our tailor-made products: pressure vessel, tanks, turbine base, metal housing, machine bed, metal flange, boilers, condenser, metal cone, pipline parts, steal beam, machine framework, steel bin, steel bridge, bearing base, tube plate, etc..

Send your request to [email protected]

Link to this article:Precision machining for a mixing silo component

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Casting Wiki,THANKS!^^