The temperature in some factories and workshops gets higher and higher as hot summer comes.

We know that temperature change will greatly affect the working accuracy of the precision Cnc Machine, which will lead to problems of the precision equipment, such as working accuracy unstable or even equipment failure. Why and how can we avoid these problems?

1 Working accuracy unstable

The influence of temperature cannot be ignored for high-precision machining because the temperature difference is the killer of accuracy. Generally, practically all substances expand when heated and contract when cooled. The linear expansion of one meter steel will be 12μm in length when the temperature changes 1 degree. This fact will not change with different locations or different equipment.

Most precision machines are made of steel, cast iron and other metal materials, whose length and shape vary with the changing temperature or the heat generated by the working equipment.

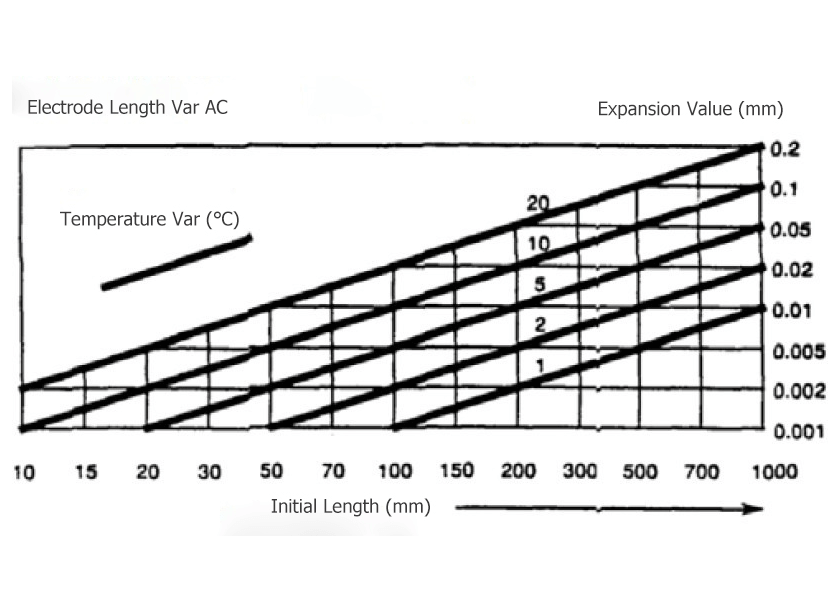

The expansion coefficient of steel as shown below:

For example:

Piece length: 200mm

Temperature difference: 10℃

Expansion value:0.02mm

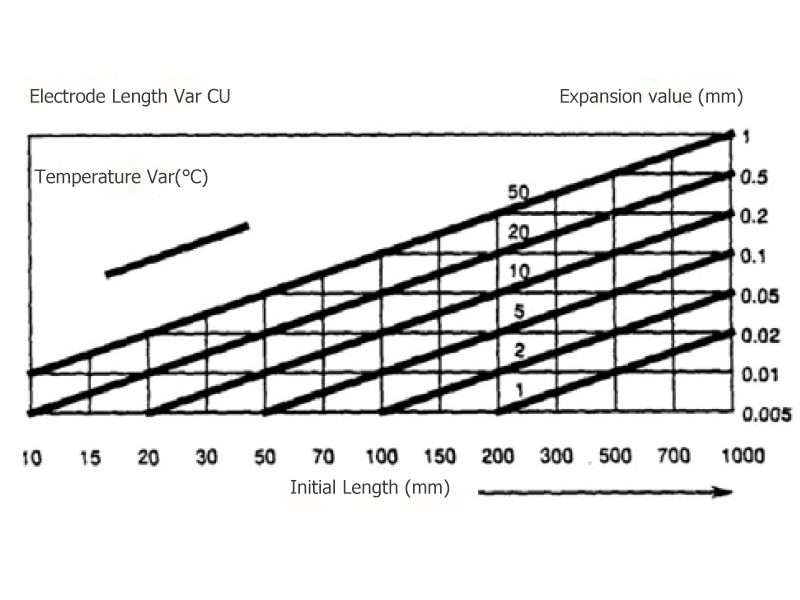

The expansion coefficient of copper as shown below:

For example:

Piece length:200mm

Temperature difference: 10℃

Expansion value:0.05mm

Factories without precision machining experience often attribute the working accuracy unstable to the precision of the equipment. While factories with precision machining experience know clearly that even high-precision machine tools can only obtain stable working accuracy under a stable temperature environment and thermal equilibrium state. They attach great importance to the environmental temperature and the thermal balance of the machine tool.

For high-precision machining of accuracy less than 3μm, the ambient temperature must be controlled at a constant 20℃ with fluctuations less than 0.5℃/hour, and the air conditioning system maintains a constant temperature with a difference of ±1℃ throughout the day.

2, Equipment failure

In summer, the temperature of workshops without air conditioner will exceed 40℃, some good CNC machine tools will inevitably breakdown. How to avoid the breakdown of CNC machine tools at high temperatures?

1) Prevent the CNC machine tools from damaging by condensate water

Many machine tools using operating fluid including machining center, slow-feeding wire cut machine, and so on. When the ambient temperature is too high, the temperature of the operating fluid will be higher. Although those machine tools are usually equipped with a refrigerator, the machine tool will shut down once the temperature of the operating fluid is too high. The purpose of a refrigerator is to ensure that the working fluid is at the same temperature as the ambient temperature by adjusting the temperature of operating fluid because the temperature of the operating fluid will rise higher than the ambient temperature during the runtime of the machine tools. In summer days, the ambient temperature may be as high as 40℃, although the machine tools can normally work for the moment if the temperature of operating fluid is set much lower than the ambient temperature for example 20℃. However, high ambient temperature and low operating fluid temperature will lead to a large amount of condensed water around the operating fluid tank of the machine. It will inevitably lead to serious rust of the parts with condensed water as time goes on. There is condensed water even at the circuit board of some machine tools, which will bring serious results.

So, the right use of refrigerator is setting the temperature of operating fluid the same as the ambient temperature. Here, there is an important precondition: suitable ambient temperature. Installing air-conditioner system to ensure a suitable ambient temperature is a basic requirement especially for precision CNC machine.

2) Prevent temperature rise of CNC equipment

For ordinary CNC equipment, many factories have not air-conditioner system to ensure an isoperibol. Some measures must be taken to ensure the normal running of CNC equipment.

(1) Ensure the air conditioner of distribution box functioning well

(2) Keep the door of distribution box closed

(3) Ensure the cooling fan of motor and circuit board function well

(4) Periodic clean the cooling ducts and radiating fin of the high-power circuit board

(5) CNC equipment should be inspected regularly to remove hidden risks

In short, the temperature control environment is very important for precision CNC equipment on hot summer days.

As a professional cnc machining service supplier, Openex is familiar with various features of metal materials such as the heat-expansion and cold-contraction. Workpieces with high accuracy requirements that need to be machined at a temperature control workshop will not be machined at a non-temperature-control workshop. On the contrary, workpieces with low accuracy requirements don't need to be machined at a temperature control workshop. Specifically, it is determined according to the customer's accuracy requirements, workpiece dimension, and the ambient temperature. We, Openex, exactly know this!

Link to this article:How to ensure the accuracy of your precision CNC machine in summer

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Casting Wiki,THANKS!^^