The unexpected COVID19 has caused a shortage of face masks. In order to alleviate the global face mask shortage amid the coronavirus pandemic, factories have been scrambling to make more surgical masks and KN95/N95 masks since February.

Generally speaking, KN95 masks and N95 masks have the same defending effect. The difference is that KN95 masks meet Chinese Standard, N95 masks meet NASI. CDC said that KN95 is on of the suitable alternatives to N95 masks and 3M has said that KN95 can be expected to function very similar to N95 masks. So wearing KN95 face mask or N95 face mask are all potential ways to prevent coronavirus. Now let’s learn more about the KN95 masks.

What are KN95 Masks?

Material analysis of KN95 masks

Executive standard of KN95 masks

How are KN95 masks are produced?

What are KN95 Masks?

KN95 masks come from the GB2626-2006 “Respiratory protective equipment self-priming filter type anti-particulate respirator”, the ‘N’ stands for ‘Non-Oil, meaning that it offers protection against solid and non-oil-based particles; the ‘95’ refers to the filtration efficiency rating. KN95 masks should be filtering at least 95% of solid and non-oil-based particles.

KN95 masks used for defending various aerosol particles (including dust, smoke, droplets, etc.) suspended in the air, but KN95 masks can’t be used for medical purposes for KN95 masks without the function of fluid-resistant and defending liquid sprays and splashes.

Some KN95 masks feature exhalation valves, which help the wearer to breathe more easily. The filtering efficient of KN95s with exhalation valves is not that good. So wearing KN95s without exhalation valves is a better choice in the situation.

Material analysis of KN95 Masks

Here is the structure of KN95 Mask (Figure 1)

Figure1

Material of KN95 Mask

KN95 masks consist of 3-6 layers of non woven fabric (here we take the case of 4 layers).

1. The outermost layer is water blocking protective layer, it is harder than others.

2. The layer of melt-blown fabric is the core material, used for barrier and filtration, to ensure excellent filtration performance, we use the highest filtering level of this.

3. The layer of the hot air-through nonwoven fabric is fluffy, soft to the touch, keep warm, prevent moisture, and improve the comfort of wearing.

4. The innermost layer is a moisture-absorbing non-woven fabric, which absorbs the moisture from the mouth and nose and keeps the surface dry and comfortable.

KN95 masks also contain these materials: bendable nose clip(most made of aluminum or iron wire)and ear bands(which is secure for fixed mask)

Melt-blown fabric is the core material of a mask. Melt-blown is mainly made from polypropylene, its fiber diameter can be 0.5~1 μm. The melt-blown fabric has characteristics of complex structures, higher hardness, good connecting strength, and excellent oxidation resistance. And the application of melt-blown is very wide:

1, Health Care: surgical gown, protective clothing, disinfection package, mask, diaper, etc.

2, Home decoration: wall covering fabric, tablecloth, bedspread, etc.

3, Clothing: lining, fusible interlining, setting cotton, base cloth of various synthetic leathers, etc.

4, Industry: filter material, insulating material, cement sacks, Geocontainer, etc.

5, Agriculture: crop covers, etc.

6, others: space cotton, insulation material, deadening, sorbent mat, etc.

Melt-blown fabric is the bonded randomly scattered PP superfine fibers together. The randomly scattered PP super fibers have more thermal bonding opportunities, which make the melt-blown material have a larger superficial area and higher porosity (higher than75%). This means that the melt-blown fabric has good air filtration. Its unique structure determines it become good and irreplaceable materials of the mask.

Executive standard of KN95 masks

The executive standard of KN95 masks is in line with international mainstream standards. GB2626 is almost the same as NIOSH, GB2626 in China is formulated based on the actual situation of China and reference to the US NIOSH standard. Here is a comparison of KN95, N95, and FFP2(Respectively executive standards are: GB2626-2006, NIOSH-42CFR84, EN 149-2001):

|

Certification/Class (Standard) |

N95 (NIOSH-42CFR84) |

FFP2 (EN 149-2001) |

KN95 (GB2626-2006) |

|

Filter performance-(must be ≥x% efficient) |

≥95% |

≥95% |

≥95% |

|

Test agent |

NaCl |

NaCl and paraffin oil |

NaCl |

|

Flow rate |

85L/min |

95L/min |

85L/min |

|

Total inward leakage |

N/A |

≤8% leakage |

≤8% leakage |

|

Inhalation resistance |

≤ 343 Pa |

≤ 70 Pa (at 30 L/min) ≤ 240 Pa (at 95 L/min) |

≤ 350 Pa |

|

Flow rate |

85 L/min |

Varied |

85 L/min |

|

Exhalation resistance |

≤ 245 Pa |

≤ 300 Pa |

≤ 250 Pa |

|

Force applied |

-245 Pa |

N/A |

-1180 Pa |

|

CO2 clearance requirement |

N/A |

≤ 1% |

≤ 1% |

Mask Types Chart. Source:3M

Definitions:

Filter performance – the filter is evaluated to measure the reduction in concentrations of specific aerosols in the air that passes through the filter.

Test agent – the aerosol that is generated during the filter performance test.

Total inward leakage (TIL) – the amount of a specific aerosol that enters the tested respirator facepiece via both filter penetration and face seal leakage, while a wearer performs a series of exercises in a test chamber.

Inward leakage (IL)– the amount of a specific aerosol that enters the tested respirator facepiece, while a wearer performs normal breathing for 3 minutes in a test chamber. The test aerosol size (count median diameter) is about 0.5 micrometers.

From the chart, it not difficult to see their similarities:

1, Filter efficient: N95 = FFP2 = KN95;

2, Respiratory resistance of N95, FFP2 and KN95 are almost the same;

3, The test agent of KN95 is the same with N95, the test agent of FFP2 can be paraffin oil.

There are also differences:

1, To be certified as a KN95 mask, the mask must fit tests on real humans with ≤ 8% leakage. Which is the same with the FFP2 mask. The N95 mask standard does not require the test.

2, To be certified as a KN95 mask, ear bands of the mask must keep 10 seconds non-breaking under a tension force of 10N.

Other differences between N95 masks and KN95 masks are that KN95 masks mostly use the ear hook wearing method whereas the N95 masks use a two head-strap, one that goes around the back of the head under the ears and another that goes on the top over the crown of the head above the ears. This really comes down to personal preference in terms of which one is more comfortable for wearers as well as the level of safety and protection one feels is necessary given the particular activity being carried out.

How are KN95 masks produced?

After the breakout of the COVID, many large enterprises in China begin to shift to produce masks. And the mask productivity of China has increased to 200 million from 30 million in less than 30 days, which is impossible without mask making machine. Mask making machine produces various masks with certain filtering performance from multi-layer non-woven fabrics through the process of hot pressing, folding shaping, ultrasonic welding, scrap removal, ear-loop welding, nose clip welding and so on. Mask making machine is not a single machine, it requires the cooperation of multiple machines to complete a variety of different processes.

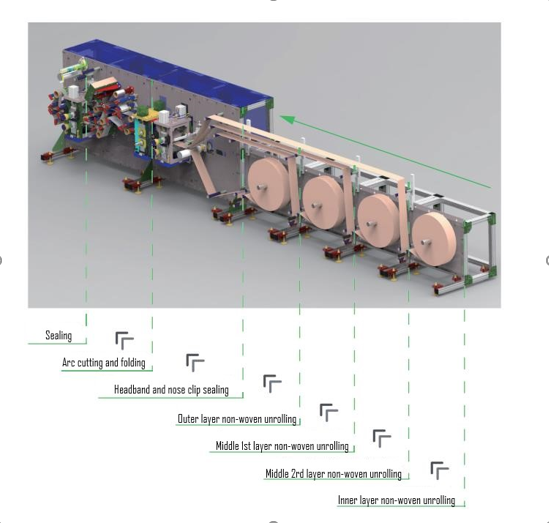

Here is the overall structure drawing of an automatic KN95 mask making machine:

Main production steps of making KN95/N95 Masks:

1, Feeding: put non-woven fabric, hot air cotton, melt-blown fabric, nose clip at the feeding area of automatic mask making machine;

2, Sealing of nose wire;

3, Press-fit: press-fit the inner layer and outlay of the mask by hot pressing;

4, Welding of earloop: weld the ear loop onto the mask by the ultrasonic welder, and the welding points will not influence the filtering efficiency of masks. It needs about 5 seconds to complete the ear loop welding of one mask.

5, Slicing: cut off the edges of the mask by stamping

6, Fold forming.

Qualified KN95 mask needs to be implemented in accordance with GB2626, clearly indicating information about wearing methods and environment, and giving reasonable suggestions to the wearer.

A mask shouldn't only be able to protect you from all the pollutant particles, bacteria, and viruses, but it also needs to be well-made and well-fitting to enhance its protective efficiency.

(Openex has designed a high efficient KN95/N95 Face Mask Machine with a capacity of 300pcs/m, whose capacity is 3 times of the KN95 face mask production lines on the market. The first high efficient KN95/N95 mask production line has been shipped to the customer’s factory and put into use. )

If you want to get more information about the KN95 Masks or KN95/N95 Mask making machine or you want to share your points, feel free to contact us at [email protected]

Sources:

https://multimedia.3m.com/mws/media/1791500O/comparison-ffp2-kn95-n95-filtering-facepiece-respirator-classes-tb.pdf

http://openstd.samr.gov.cn/bzgk/gb/newGbInfo?hcno=16D8935B45AD7AE40228801B7FADFC6C

Link to this article:What are KN95 Masks and how are they produced?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting.:Casting Wiki,THANKS!^^